Typhoon® Valve System is the latest result of the Mokveld vision. Implementation of the Typhoon Valve System is a simple and efficient solution to enhance oil-water separation and achieve compliance to corporate goals for a sustainable production of fossil fuels in an environmentally sound manner.

This low shear valve solution minimizes droplet breakup and the formation of tight emulsions. Separation and produced water treatment systems benefit from the improved separation of oil-water. This low shear valve is used to reduce oil in water (OiW) concentration and water in oil (WiO) concentration, or alternatively, to increase production is existing facilities.

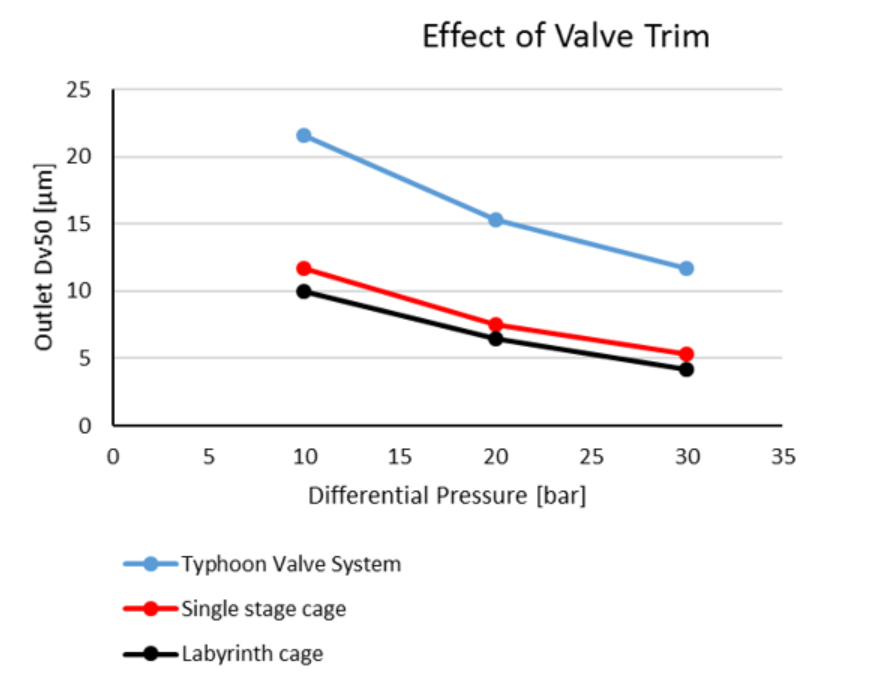

Emulsification and droplet break-up in mixed petroleum phases are directly coupled to turbulent shear forces in throttling valves. These shear forces are a function of the volume involved in the energy dissipation. Where most valve designs dissipate the energy within the cage, the Typhoon Valve System dissipates the energy by means of a patented cyclonic flow pattern through the system.

The low shear Typhoon Valve System activates a much a larger volume in the dissipation of the energy.

The patented technology outperforms any other valve designs such as labyrinth or drilled hole cage solutions with regard to shear reduction.

The Typhoon Valve System can:

• reduce the Oil in Water (OiW) concentration with 30% to 60% without any modifications to the separator

• reduce the use of process chemicals like emulsion breakers, flocculants and clarifiers are required

• reduce the environmental impact of the facility (EIF)

Reduction of the turbulent shear forces enhances separation for all process and operating conditions

• High to low water cut

• High to low pressure drop

• High to low API gravity

Erosion or corrosion resistant materials are standard to increase operational lifetime, similar to the standard Mokveld valves.

Incorporating the best valve technology has made Mokveld the primary choice for choke and flow control solutions worldwide. The Typhoon Valve System extends the application range of Mokveld providing customers a simple means to achieve corporate sustainability and environmental goals.

If you would like to have more information about this product, please contact us. As experts in engineered valve systems, we are capable of providing reliable customer services and can support you with valve sizing and selection, process engineering and system lay-out and budget pricing.

Development

The Typhoon Valve System is developed in close cooperation with Typhonix A/S in Norway.

Learn more about low shear theory and technologies at lowshearschool.com or visit their website typhonix.com.

Discover more about our Low shear Typhoon Valve System:

In case you want to reduce your Environmental Impact Factor (EIF) by improving downstream separation, debottlenecking your separation or produced water treatment system or if you want to improve your system robustness, please contact your Mokveld support office or representative for more information about the possibilities with this low shear technology for your application.