Advantages of HIPPS

HIPPS provides a technically sound and economically attractive solutions to protect equipment in cases where:

- High pressures and / or flow rates are processed

- The environment is to be protected

- The economic viability of a development needs improvement

- The risk profile of the plant must be reduced

What is HIPPS (or HIPS)?

HIPPS is an instrumented safety system that is designed and built in accordance with the IEC 61508 and IEC 61511 standards. These international standards refer to Safety Instrumented Functions (SIF) and Safety Instrumented Systems (SIS) when discussing a solution to protect equipment, personnel and environment. A system that closes the source of over-pressure, with at least the same reliability as a safety relief valve, is usually identified as a HIPPS. Systems using other sensors may be called HIPS, High Integrity Protection System. Generally both HIPS and HIPPS require a Safety Integrity Level SIL3 and a Systematic Capability SC3.

The systems can also be designed to EN12186, the final elements are in compliance with EN14382.

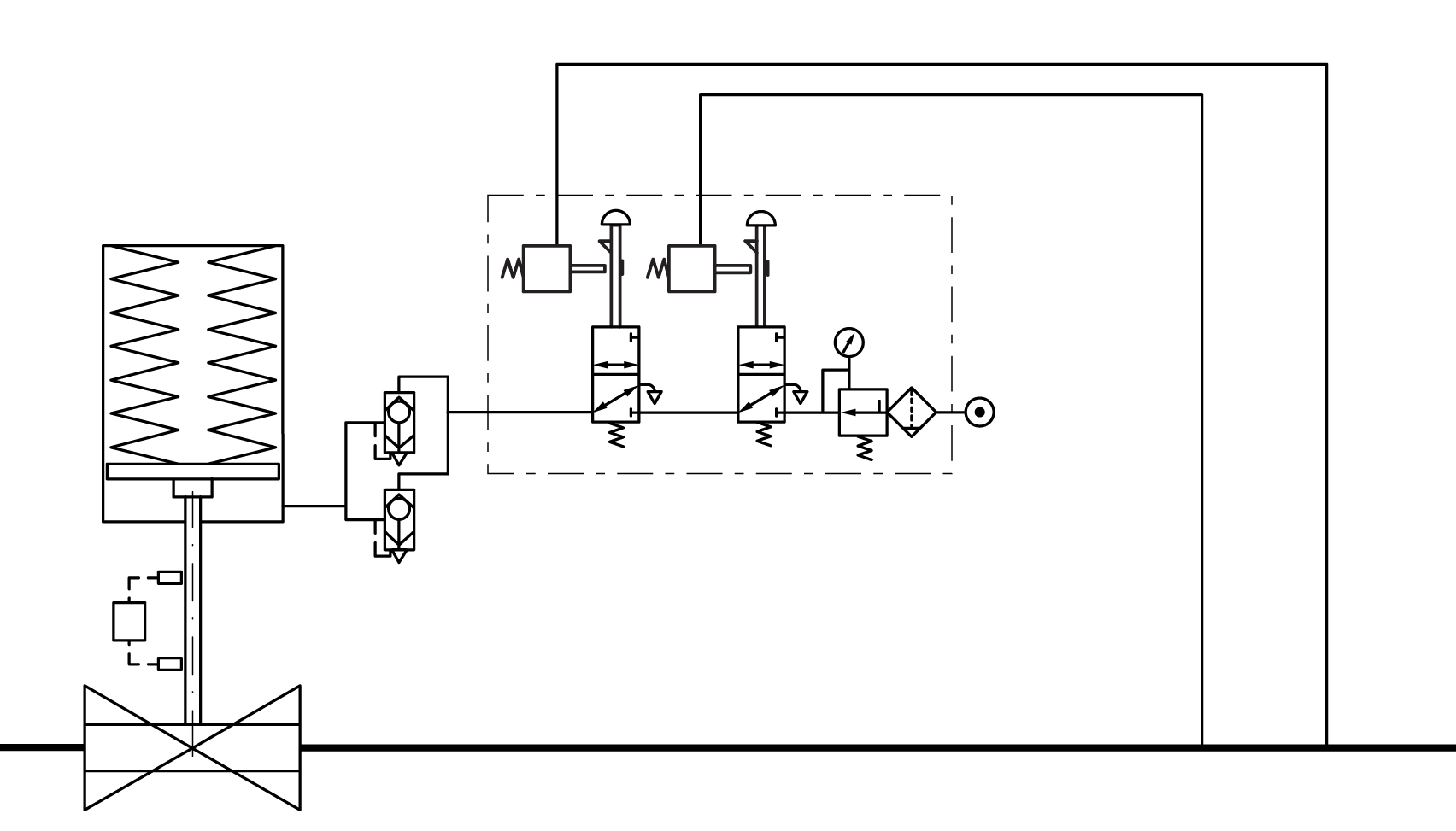

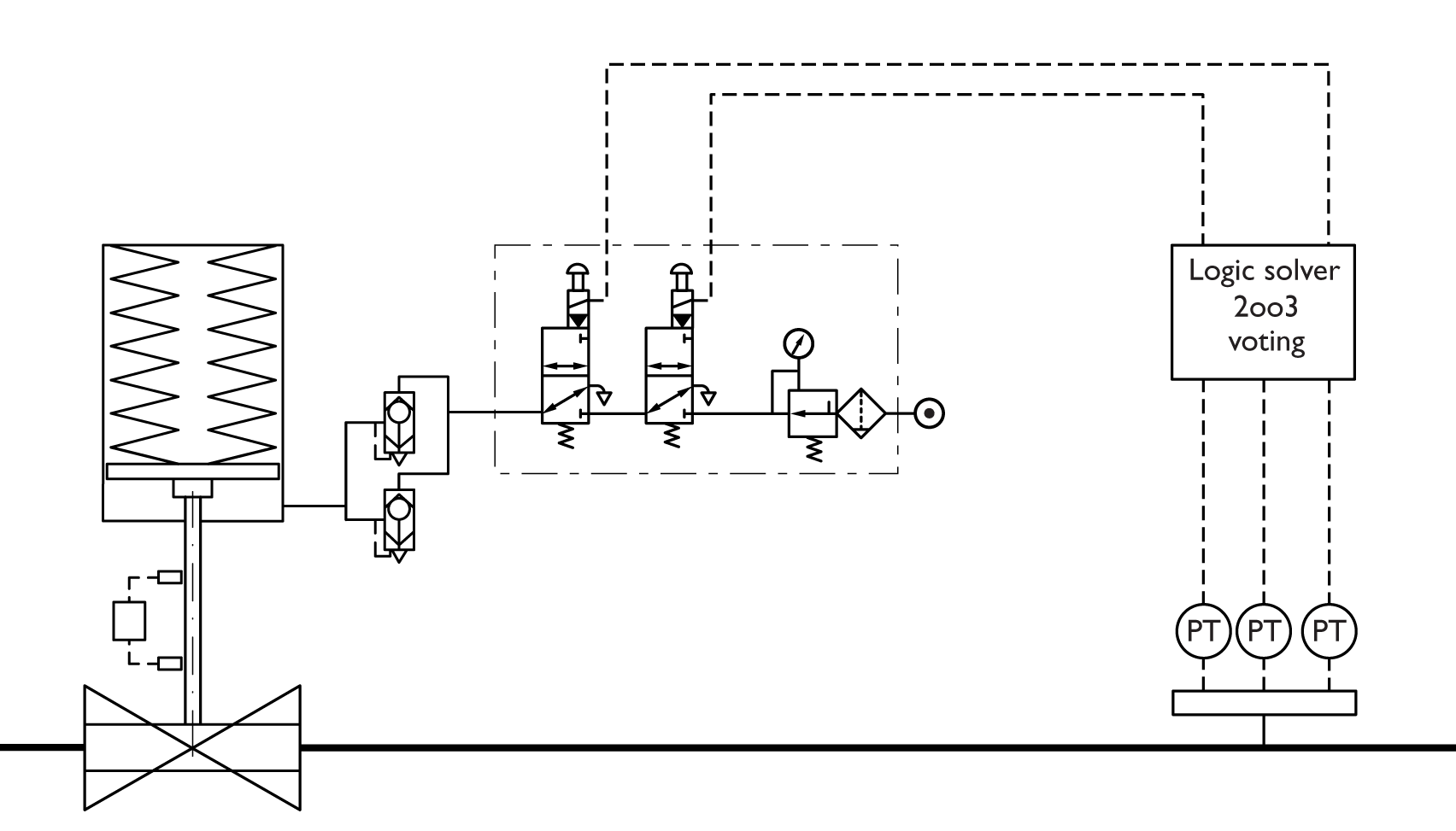

A HIPPS or HIPS is a complete functional loop consisting of:

- Electronic or mechanical initiators, the sensors. For HIPPS these detect the pressure

- For electronic HIPPS, a logic solver, which processes the input from the initiators to an output to the final element.

- The final elements, that actually perform the corrective action in the field by bringing the process to a safe state. The final element consists of a valve and actuator and possibly solenoids or mechanical initiators.

Mokveld reliability

Third parties, like the German TÜV and Atomic Energy Agency, have validated the Mokveld field data and derived reliability data for the valve actuator combination.

Failure rates for both clean and unclean fluids are available for 2 seconds stroking time applications.

Mokveld’s vast experience in fast stroking final elements totals over of 50 000 operational years (with more than 3.700 final elements). The Mokveld final elements are therefore proven-in-use for high reliability safety applications in upstream and downstream Oil and (hydrogen) Gas service.

The third party certified failure data enables Mokveld to supply safety systems to suit SIL3 or even SIL4 with proof test intervals that may exceed 1 year.

The Systematic Capability (SC3 / 4) is confirmed by the Functional Safety Management System (FSM) in accordance with IEC 61508 and IEC 61511. The safety systems will be designed and integrated by Functional Safety Engineers (FSE’s) present in all departments across the company.

The Mokveld final elements do not require additional electronic systems, like partial stroke testing devices, to meet SIL 3 with a 1 year test interval. A separate technical datasheet on this subject is available.