Flare Gas Recovery with a fail open HIPPS

With Flare Gas Recovery (FGR) the flare gas is recompressed rather than sent to the flare continuously. This gas is either brought back into the process, or compressed in trucks for further usage elsewhere. Normally flow to the flare is blocked thus reducing routine flaring.

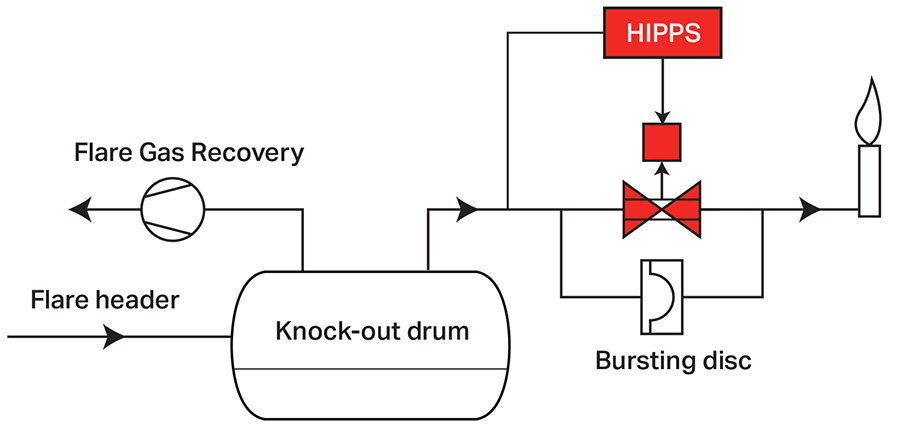

Figure 1. Flare Gas Recovery

All equipment upstream of the booster compressor is designed at low pressure. In case of increased flow to the flare header, as a result of valves opening in the relief system, the flow shall be directed to the flare while the booster capacity is too low. A High Integrity Pressure Protection System (HIPPS) senses the increasing pressure and opens the fast opening valve to avoid over-pressure in the upstream process. The flow to the flare is opened and the flare can be ignited. High reliability is required to protect equipment and personnel therefore field proven equipment shall be used.

Bubble tight shut-off is required to avoid fugitive emissions to the flare and atmosphere. Mokveld’s patented sealing system assures this bubble tightness over the life time even when solids are present in the fluid (e.g. rust from the pipe wall).

Third party certified failure data for fail open applications are available confirming suitability to achieve a SIL3 protection level using Mokveld axial flow HIPPS valves complete with actuators. These data apply to complete final elements opening in less than 2 seconds.

Near zero flaring with fail close HIPPS

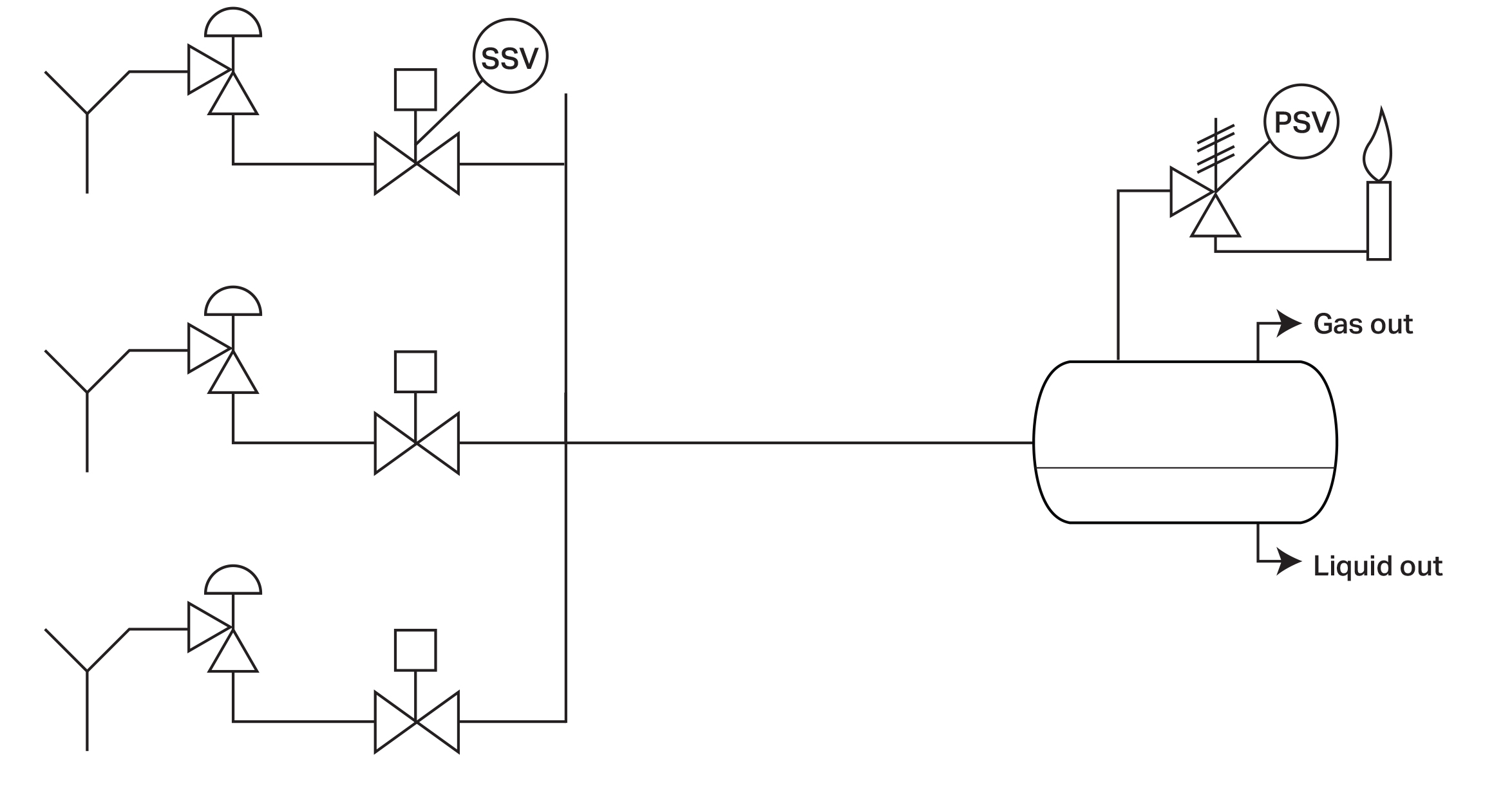

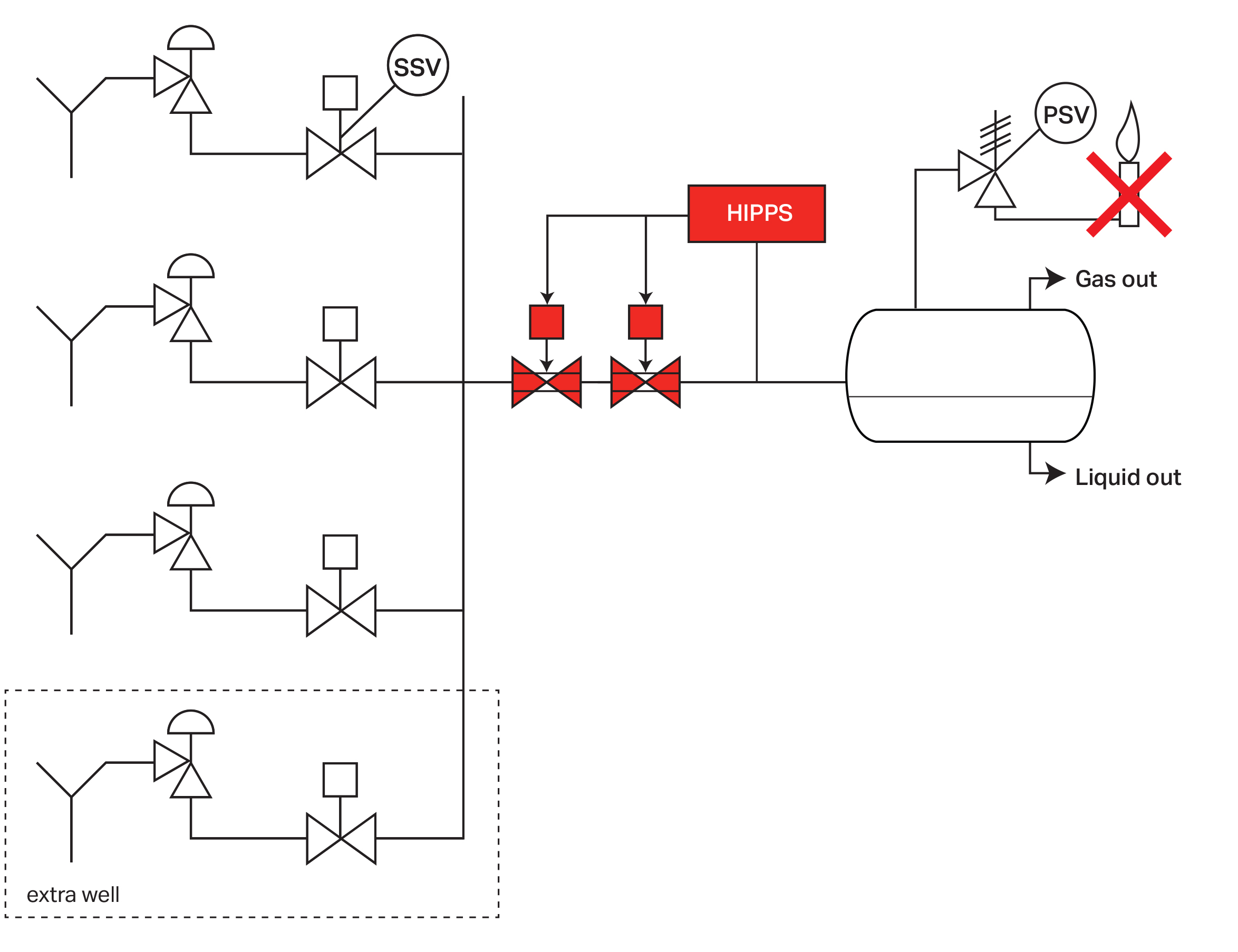

In cases where regular flaring occurs due to limited production capacity downstream, HIPPS are a safe and very cost effective solution. For instance, the addition of extra wells to separators may result in regular unwanted flaring (figure 2.). HIPPS then closes the source of the over-pressure rather than to open a relief valve to a flare system and as such reduces emissions by flaring (figure 3).

Figure 2

Figure 3

Third party certified failure data are available confirming suitability to achieve a SIL3 protection level using Mokveld axial flow HIPPS valves complete with actuators. These data apply to complete final elements closing in less than 2 seconds.

In case of more interest or a request for Mokveld assistance in designing the full system to achieve zero routine flaring, click on the ‘Contact Mokveld’ button below the engineering assistance information text.