Mokveld's expertise in zero-cavitation control valves has once again been demonstrated at the Central Utah Water Conservancy District’s (CUWCD) Sixth Water Flow Control Structure in Utah, where two 24" and 32" (DN 600 & DN 800) axial control valves with zero-cavitation trim were successfully installed and commissioned. The new valves seamlessly handle the demanding task of breaking 560 psi / 400 mwc (39 bar) to atmospheric pressure without cavitation, vibration, or excessive noise.

The Sixth Water Flow Control Structure (SWFCS) is a crucial component of the Diamond Fork System, responsible for transporting water from the Wasatch Mountains to the populated Wasatch Front region. The system conveys an annual average of 101,900 acre-feet of Central Utah Project (CUP) water, making it essential for water supply and hydropower generation.

Mokveld's Solution: High-Energy Dissipation Valves

The addition of the two Mokveld axial control valves by means of a modification of the SWFCS was necessitated due to control and cavitation issues of the two existing 54” submerged sleeve valves at the facility, particularly at lower flow rates due to the high differential pressures (dP). Mokveld's solution involved installing one axial control valve with anti-cavitation trim per train, offering a flow capacity range of 5 to 50 cfs and 10 to 100 cfs (or 500 to 5,000 m3/hr and 1,000 to 10,000 m3/hr), respectively. This configuration effectively addresses the varying flow demands of the Sixth Water Flow Control Facility.

Exceptional performance and Optimizes noise reduction

The successful commissioning of the energy dissipating valves in spring 2023 has been followed by flawless operation throughout the summer. The valves have consistently demonstrated their ability to break 560 psi (39 bar) to atmospheric pressure without cavitation, vibration, or excessive noise. This achievement highlights Mokveld's commitment to delivering reliable and high-performance solutions for challenging water and hydropower applications.

One of the most notable aspects of the project is the significantly lower noise level within the vault, approximately 20 dB(A) lower than anticipated. This is likely attributed to the valves' almost free discharge into an adjacent energy dissipation chamber, demonstrating Mokveld's ability to optimize noise reduction in addition to performance.

Notably, no other comparable valve type, such as plunger or sleeve valves, could have met the project's stringent requirements in such an impressive manner.

Comprehensive Support and Documentation

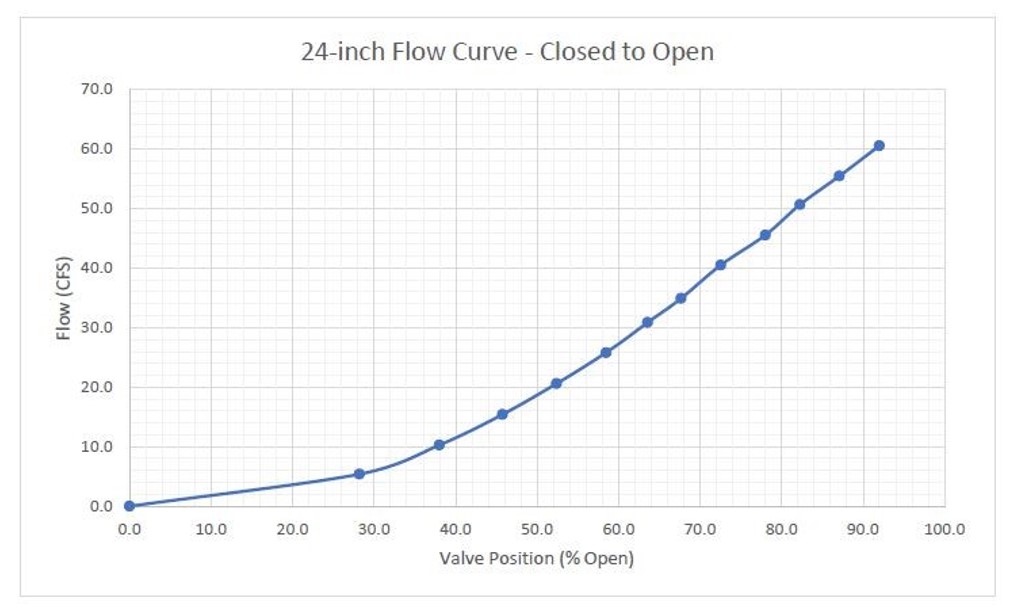

Mokveld After Sales provided comprehensive field support during the startup phase, ensuring a smooth transition to the new valves and maximizing operational efficiency. Additionally, the U.S. Bureau of Reclamation, overseeing project operations as a federal facility, meticulously documented the results of the on-site flow performance testing. The measured flow curve closely matches Mokveld's valve characteristic curve and is virtually identical to the calculated sizing predictions. This rigorous testing and documentation further validates the reliability, quality, precision, and ultimate performance of Mokveld's axial control valve design in critical applications.

Read more about:

In order to ensure you continue to benefit from valves that offer high capacity and safety as standard, we offer a range of modernisation services. For more information about our modernisation services, please contact your Mokveld support office or representative.