Axial flow valves with proven reliable performance will help to reduce costly maintenance and lost production time; a choice that will ensure the safe and reliable operation of your plant.

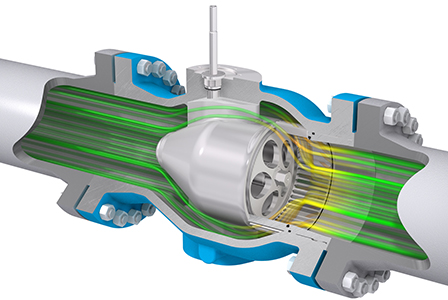

Since the early 1900’s an exceptional valve concept was used in hydro power plants: the axial flow valve. Axial flow refers to the streamlined symmetrical and unrestricted flow path between the valve inner and outer body. In the 1950’s Mokveld acknowledged the unique advantages and adopted the concept into their on-off and control valves designs. Over the last decades those axial valves captured a strong position across the full range of gas and oil segments; production, processing, transmission, storage and distribution. The design has also proven to be the preferred solution for special water applications.

By nature of design the axial valve has unique benefits that make the valve specifically suitable for the more special and severe service control and safety applications. The axial valve solutions that we offer today are the evolution of all the valves that have been developed over the past seventy years. Axial flow has evolved from a unique concept to a mature design.

Streamlined flow path through full-port expanded body

Valve selection is often based on outdated design philosophies and capital expenditure (valve price). However, control and safety valves can be critical elements in a process system. Malfunction or failure of a valve can seriously affect plant operation, the environment and your bottom line. Valve selection should be based on sound technical and economical arguments and long-term perspectives. Selecting Mokveld axial valves with proven reliable performance will help to reduce costly maintenance and lost production time; the selection to ensure safe and reliable operation of your plant.