Mokveld Valves BV from the Netherlands has supplied Engineered Valve Systems to USA customers since the 1970’s. To serve the market better and show our commitment Mokveld USA Inc. was established in 1987, with an office in Houston. We are proud to celebrate over 30 years of activity in the United States, and we would like to thank our customers for recognizing our commitment to the US market.

On this webpage we would like to briefly share some of our historic and more recent references in the various market segments.

Prudhoe Bay Oil Field on Alaska's North Slope is the largest oil field in North America. Production began in 1977. Over the decades Mokveld supplied more than one hundred angle and axial choke valves both for the production of oil and injection of gas.

The Louisiana Offshore Oil Port (LOOP) is a deep-water port in the Gulf of Mexico off the coast of Louisiana. LOOP provides tanker offloading and temporary storage services for crude oil transported and handles as much as 13 percent of the nation's foreign oil. As reliability is key LOOP has selected over 50 large Mokveld axial check valves and control valves with high capacity or anti-cavitation trims (10 – 48”).

The liquid transportation network in the USA is immense with about 200,000 miles of pipelines ranging in size from 2” to 48” in diameter. Each day > 38 million barrels of crude oil, feedstocks and products is transported. To minimize pumping energy loss Mokveld axial check valves have been the preferred choice by the operators. In older pumping stations - because of issues related to water hammer - existing swing type check valves are being replaced with our non-slam check valve design.

Also the gas transportation network is huge; more than 305,000 miles of gas transmission pipelines with over 1,400 compressor stations. Initially our contribution to this segment was limited high reliable / low pressure loss check valves for compressor stations.

Recent 3 years most major gas pipeline operators have also familiarized themselves with our compressor anti-surge control and fast stop valve solutions. Conventional systems using globe or ball type control valves require a bypass with additional fast stop valve to obtain sufficient capacity and control accuracy. As the Mokveld axial control valve combines accurate control with a very high (quick) capacity that bypass can often be eliminated. The considerable cost savings have contributed to quick acceptance of this new solution.

The gas transportation network also has thousands of receiving and interconnection points, hubs and about 50 locations where natural gas can be imported/exported via pipelines. Vector Pipeline has large Mokveld control valves installed in 5 critical meter stations (buried service) since 2002.

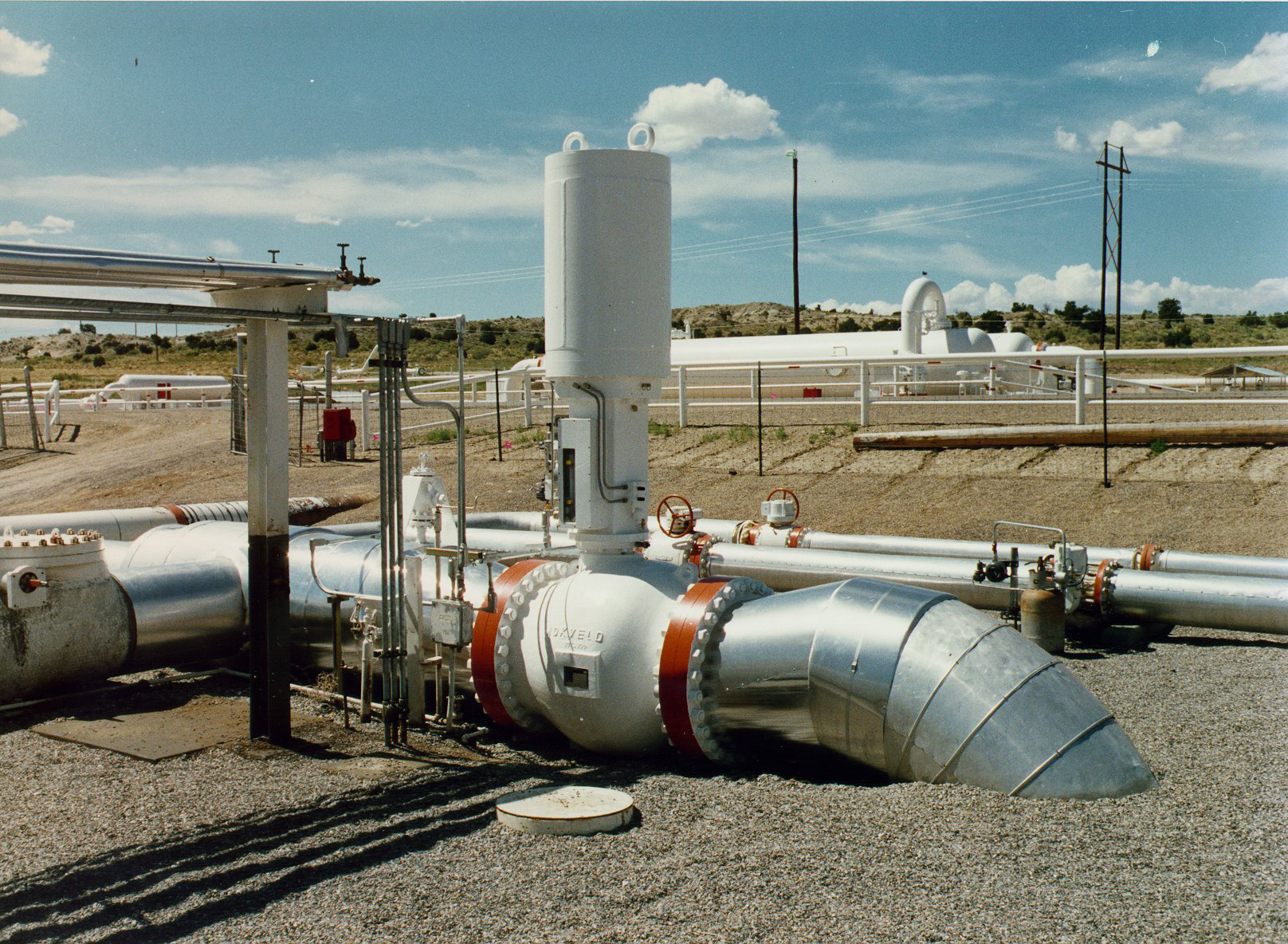

Important for reliable supply of gas during high demand situations are the 400 underground gas storage facilities. Mokveld axial control valves (or axial choke valves) are bi-directional and used for combined injection and (re-)production service and suitable for harsh environmental conditions down to -76 °F.

With the rapid growth of supply from shale gas resources over the past decade, U.S. natural gas production has grown each year since 2006. The resulting decline in domestic natural gas prices has led to rising natural gas exports, both via pipeline to Mexico and to overseas markets via LNG tankers. The first LNG export terminal (in the Lower 48 states) is the Sabine Pass facility in Louisiana which became operational in 2016. By 2021, four LNG export facilities currently under construction are expected to be completed. Combined, these five plants are expected to have an export capacity of 9.2 billion cubic feet per day.

Mokveld supplied 48” – 68” axial check valves on the refrigerant compressor discharge of Freeport LNG terminal.

A growing market where our brand is expanding. Colorado Springs (Utilities) – at the base of the Rocky Mountains – installed its first Mokveld axial control valve into a hydroelectric power generation facility in 1993. Because of relatively high pressure drop – from the lakes high up in the mountains down to the city in the valley – the process had a tendency to cavitate and with a special trim we were able to avoid the cavitation.

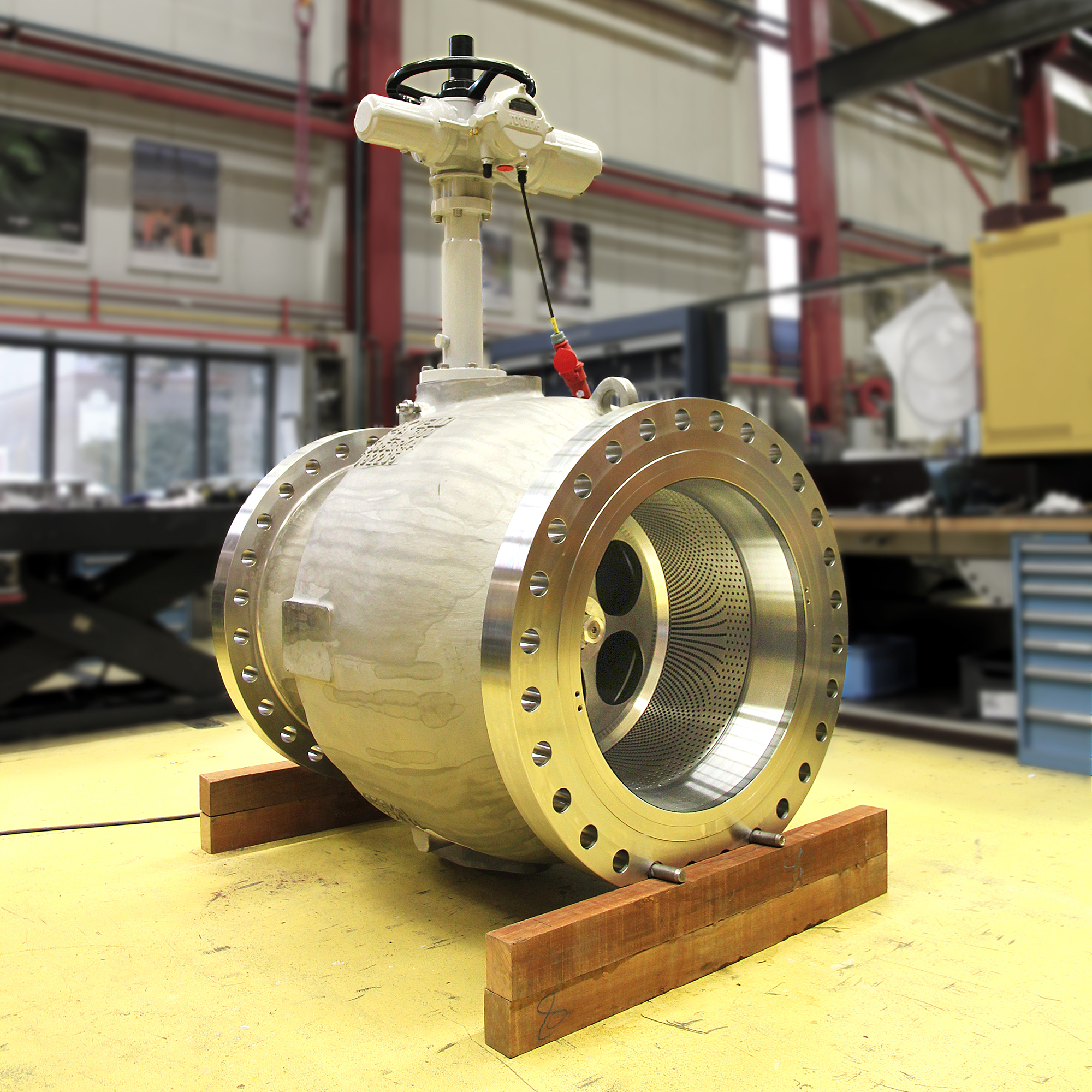

In addition municipal water systems have specific operations that require critical management of the flow of water (e.g. between treatment plants). If a valve failure prevents potable water from reaching people within a city, major issues can develop quickly. Reliability, flexibility (bi-directional) and high capacity are essential. Recently again, we supplied 2 x 30” axial control valves to a Utility provider. The Duplex valve was custom designed with a hybrid cage consisting of 10% stroke with anti-cavitation features (RMX) and the remaining 90% stroke with high capacity trim (RECX) and equal% control characteristic.

And – indeed – the largest valve we ever produced was supplied to the USA; an 84” axial check valve.

Switching US cracker feedstocks to cheaper domestically produced ethane has resulted in a decrease in the associated production of propylene. Enterprise’s PDH plant (propane dehydrogenation) – with a production capacity of 750,000 tonnes per day – will utilize growing supplies of domestically produced propane to provide another source of polymer-grade propylene to meet this shortfall.

Mokveld axial flow valves are ideal for offshore platforms and FPSO’s but not only because of its low weight and compact design. Recently a major USA Oil and Gas company installed its first Typhoon Valve on a platform in the Gulf of Mexico. This (smart) valve will enhance the oil and water separation process resulting in cleaner water (> 50% improvement) and / or increased oil production.

2022 was our centennial anniversary. Soon after founding in 1922 Mr. Mokveld started production of in-house products and the rest is history: 100 years of innovation and craftsmanship and originator of the axial valve for oil & gas, hydrogen and CCS applications as well as for critical applications in the hydropower and water industry worldwide.

Mokveld USA Inc. Team 2025

For further information about the above references or Mokveld Engineered Valve Solutions please contact our Mokveld USA office in Houston via +1 281 599 37 77 or usa@mokveld.com.